Track & Bridges

Turnout Guard Rail Repair

Dec 3, 2003

By John B. Pedersen |

Author

Bio

One of the most aggravating things that happens during train operations is when you have a derailment while running thru a turnout.

|

One of the most aggravating things that happens during train operations is when you have a derailment while running thru a turnout. Most of the time it happens while running into the points, but it can happen in either direction.

It seems to happen at the most inappropriate ( make that embarrassing ) times, like when company comes by and you can't seem to get down the track more than once or twice before IT happens again. Because of space limitations I started with 4 foot diameter curves with #4 turnouts, so engine size was limited. One of the "pride of the fleet", is an Aristo Pacific. With great care and slow speed it would transverse the #4's maybe 3 out of 4 times. I read in the LSOL forums about back to back wheel measurements, so I regauged the wheels and this got better, but not as good as I and many others would like. I changed some of the sharper curves to 5 foot and installed some extra wide turnouts, closer but still no cigar, so being the tinkerer I am, I set to try to figure this out. I checked the back to back on the wheels and got several sets right on the button. They went thru the points OK, but they bounced thru the frog. The wheels were running into the frog point, dropping down into the frog if they weren't deep flanged wheels. You cannot move the inside guard rail with LGB and AC turnouts. I had one in particular that was troublesome due to the inner rail getting broken off at the point. The wheels hit it like a wall and decided to take the low road instead.

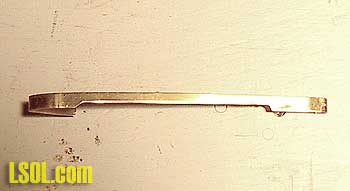

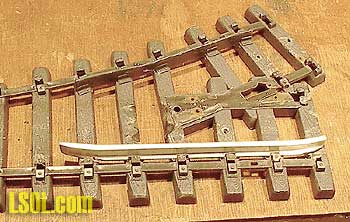

I started by taking a piece of .015 x 1/3" brass stock and filed it to fit down between the guard and main rail. I filed the profile so as not to get hung up on the fish plates.

I put a long piece of heavy brass round stock 1/16" at one end and soldered to the brass. I bent the other end into a "U" shape to fit around the guard rail.

This was put in place on the damaged turnout. Now the wheels went thru much better. I then noticed it just barely cleared the frog point. So I put a small "bow in the piece of brass headed towards the main rail, about center.

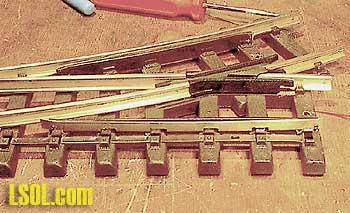

The new rail pulled the wheels toward to outside of the turnout and missed the frog point completely. This was the beginning of several different techniques for guard rail improvement. Next I made a piece with bends on both ends and crimped it on at each end.

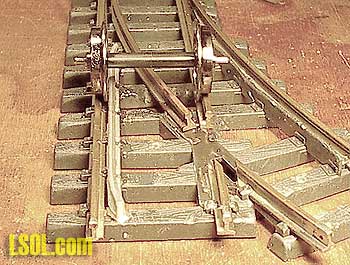

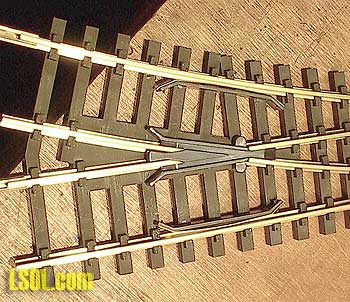

This was not good because there was no "give" to the new guard rail. I eased the crimp on one end so the brass could move and it was like day and night the way it operated. I knew I was on the right track ( no pun intended, but what the heck ). I removed the rails next and using the same idea, except I screwed the brass to the old guard rail. I also filed the brass to clear each individual plate, even thought it does not seem to help or hurt. (im002200) I also made one hole oval for movement of the brass guard rail. This also works well and the new brass guard can't fall off or get knocked off the turnout if the crimp loosens.

The new rail kept the wheel where it needed to be. The brass pieces can be painted black to hide them. Black acrylic paint will stick to the brass and can be brushed on. It is also water cleanup. The wheels will remove some paint on the new rails so you can see how they are operating. The next thing to try was a completely new guard rail installed on a #4 turnout. I first used a razor saw to cut out the existing rail, which was not real easy, and filed the ties smooth.

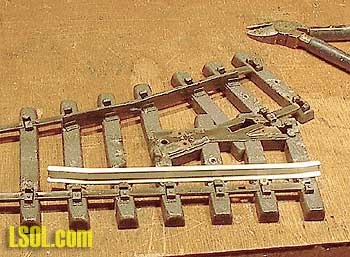

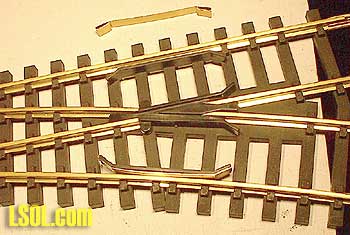

I cut some aluminum rail, because that's what I had in stock, I used a small vice and file to bend and shape the new rail to approximately the same shape as what I removed.

When the new rail was held in place, the bottom of the rail would not allow it to be placed close enough to pull the wheels as I wanted. I filed the bottom of the rail to fit over the fish plates.

This gave me the clearance I wanted ( needed ).

I temporarily set the rail with hot melt glue and marked where to drill the holes for the mounting screws. I marked the ties and drilled small holes, and marked the rail.

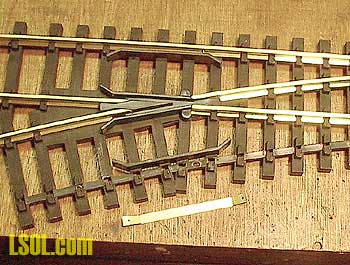

Using a small drill press I drilled the rails and tapped for a 2-56 screw. It just so happens that AC uses that very size for rail joiners. I made the holes in the ties slightly oval for a small bit of adjustment. I did both rails and took it outside and installed a temporary siding. The modification worked well and my Pacific had no problem going thru even at moderate speed, around a scale 30 MPH. The biggest thing I noticed was backing up a string of cars thru the turnout. It kept the wheels away from the frog point and even with 12 cars no problem backing into the siding. This rail can also be painted if desired. I turned my attention to the new extra wide turnouts, as they had the same problem. I removed the rails and tried the bent ends over the guard rail.

This didn't work too well because the rail is so short, that the brass wouldn't flex properly. I went back to screwing the new brass to the inside of the old guard rail.

These gave the flex needed without creating problems.

The next thing I tried was to put a piece of .010 brass on the bottom of the frog where the flanges run.

This took the hop out of running thru the frog, and was a much smoother transition into the turnout. The problem is if you have any cars with deep flanges they jump up as they go thru. I use semi scale wheel flanges on most cars with exception of my AR Sierra passenger cars, so they jump thru one turnout. Now no turnout gets installed till I do these modifications first, it is well worth the time and trouble. These modifications can be done by almost anyone and a few hand tools are all that is needed. You can drill thru the rail with a hand held drill as long as you go slow and steady, and if you use AC rail you probably have the tap needed. I get most of my small screws thru Micro-Fasteners, and they have the taps also. Some good old fashioned hardware stores also keep some smaller stock on hand. We have a couple in this area. Happy Railroading, John B Pedersen, JFF & NSI Railroad Top of Page

|