Track & Bridges

Aristo-Craft "Y" Switch Review - with VIDEO

May 23, 2007

By Jon D. Miller

LSOL.com Reviews Editor |

Author

Bio

After much speculation and a rather long wait the new Aristo-Craft Y Switch arrived last week. From our first impression it was worth the wait.

|

Watch the Video

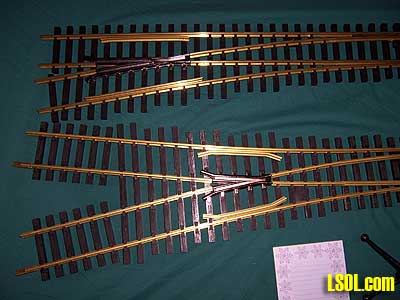

After much speculation and a rather long wait the new Aristo-Craft Y Switch arrived last week. From our first impression it was worth the wait. Now folks that want to construct a Wye that is symmetrical the new Aristo Y Switch is the solution. LET'S TAKE A LOOK:  The new switch comes packed in the now familiar yellow box, protected by foam inserts at each end. Ours arrived in excellent condition. No bent rail joiners on this one. Here are two views of the switch out of its box. Just like its cousin the Aristo-Craft #6 switch this one is long.

The Y switch is 35 3/4 inches long. That compares to the # 6 switch that is 35 5/8" long. So the Y is just a tad longer. The frog on the Y is 4 inches long compared to the #6 that has a 6 3/8" frog. Frog length on both was measured along the wing rail.  Here's a closer look at one of the guards and wing rails on one of the diverging sides. Note that Aristo has changed the guardrail to match the wing rail on this Y switch. Also note that the ends of the guard rail are now turned in slightly at the ends in a more prototypical fashion.

This picture shows the frog with a view of both guardrails.  Pictured is the frog and guardrail. By measurement, Aristo-Craft has reduced the flangeway space between the guardrail and the stock rail. The reduction of flangeway width should eliminate the tendency for wheels to hit the frog point. A too wide flangeway on many of the # 6 switches causes wheels to hit the frog point when going through the switch point facing. All applicable tolerances were checked with the Aristo-Craft ART-11906 Track and Wheel Gauge. Point spread, guardrail flangeway depth and width, wing rail flangeway depth and width, guardrail span, and track gauge were all within tolerances of those called for by the Track and Wheel Gauge.

This is a top view of the screws that hold the polarity micro switch in place.  The ground throw is the same as used on other Aristo-Craft switches. However, it seemed to me that there may be a stronger spring in the ground throw. Point action seemed to be more positive when throwing the points.

Here are two views of the polarity switch mounted under the switch. Note the silver lever. There is a brass pin that moves against this lever that in turn caused the frog polarity to change. My #6 switches are a few years old. They still have the little micro switch that in many cases does not work. Possibly this change of the switch will correct the problem. For outdoor use, Aristo-Craft recommends coating the switch and lever with grease. One thing is certain, these switches can not be floated on or pushed down into the ballast. The Y switch, due to its length and the micro switch, will have to be mounted on a substantial flat base.

Pictured is one of the buss wires that power the rails. These wires and their attaching screws look just like those on my #6 switches. For outdoor use it would be wise to use a conductive paste or grease on these screws to maintain good electrical contact and to retard rusting.  Here is the Y switch next to a #6 switch. Of note is the frog position on the two switches. As previously mentioned, the frog on the Y switch is shorter than that of the #6 switch. Also, note the location of the frog. On the # 6 switch the frog sets closer to the diverging rails.

I took the Y switch out by the rock garden to do a temporary setup. While my back was turned a small business district sprung up! The Y switch was placed directly on the ground. A number of 5 foot sections of track were added to the switch. I ran an RS3 with two cars back and forth through the switch. Even with this temporary setup the switch functioned without a problem. From this very short test it does appear that the Y switch will do its job, given proper installation and maintenance. CONCLUSIONS: A nit. The point rails are held in place at their pivot point and at the point bar by small screws. Each screw has a very small spring under its head. This spring is to allow the points to move freely. However, the spring does allow the point rails to rock slightly. I don't think this will be a problem, but it bears watching. During the short outdoor test I could not detect that the point rails were going to cause a problem. The point rail, held tight against the stock rail does not rock. From checking tolerances, it appears that the Y switch, at least the one tested, was built to closer tolerances than any of my # 6 switches. So, possibly Aristo-Craft has learned from its past experience with the #6 switch. It seemed to me that the rails in the Y switch are held tighter by the ties. On some of the #6 switches that I have, track gauge varies and the rails will move slightly in and out of gauge. I don't think I'll tear out my Wye to install a Y switch. If I did not already have a Wye that uses a #6 turnout at the apex then one of these new Y switches would be in order. Top of Page

|