Scratch & Bash

:

Engines / Rolling Stock

Updating Trucks on USA Covered Hoppers

Oct 11, 2006

By Ron Hill |

Author

Bio

I recently purchased the new USA center flow covered hopper freight cars at the South East Large Scale Train Show in Perry, GA. When I started changing out the truck, I discovered that there was a difference in the depth of the bolster frame between the USA and A/C trucks. What to do?

|

Changing Trucks on USA Covered Hoppers | I recently purchased the new USA center flow covered hopper freight cars at the South East Large Scale Train Show in Perry, GA.  As I started changing out the knuckles from USA to Aristo-Craft, I discovered that the extension and knuckle were metal.

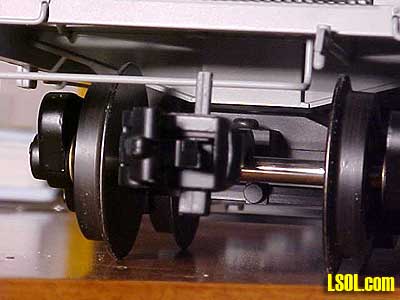

This presented a situation where either I had to do some cutting, grinding and drilling to make it possible to connect an Aristo-Craft knuckle to the extension, or change out the entire truck completely. I decided to change out the entire truck. When I started changing out the truck, I discovered that there was a difference in the depth of the bolster frame between the USA and A/C trucks.

The USA bolster frame is 7/16" in depth.  The A/C bolster frame is 1/4" in depth.

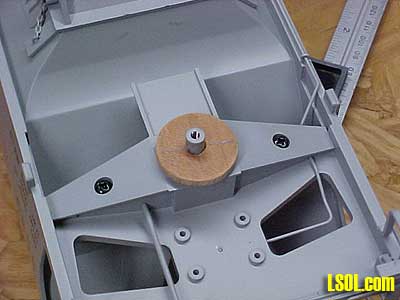

This makes the difference between the two trucks of 3/16". The covered hopper has a center plate that is 1/16" thick and this has to be taken into account when designing a spacer to make up the difference between the two different trucks.  The thickness of the spacer works out to be 1/8" after the 1/16" center plate thickness is subtracted from the 3/16" depth difference of the two trucks. I made the diameter 1" to add as much stability as possible.

A 1/4" diameter hole needs to be drilled through the center of the spacer for the center post. The spacer can be made of most anything that has a smooth surface. I made mine out of some cherry wood that I had lying around the shop because I did not have any 1/8" styrene.

When the spacers are made and in place, the vertical distance on each end of the freight car from the track should be the same.   Top of Page

|

|