Scratch & Bash

:

Buildings

Precision Board in the Garden Railroad

Sep 3, 2008

By Peter De Keles |

Author

Bio

Come read about how an obsession with starting a Garden Railroad became a discovery of a unique building product, that grew to a exciting business for the Garden Railroad industry. Ross and Sue have been members of LSOL.com since 2003. Come and read about the products they offer and how it just might change how you build your Garden Railroad.

|

There are many stories of how people came to be garden railroaders. A good majority of them seem to involve not wanting to put away the train running around the Christmas tree, adding a loop here and there, and removing unnecessary obstacles by giving sofas and dining room tables to the Salvation Army. Eventually, someone puts their foot down and agrees to give up part of their yard for a layout if they can just have furniture back in the house or park their car in the garage again  Ross and I were on our first real vacation together in 1996. While driving through Truckee in Northern California, he hung a quick U turn and stopped in front of a toy store where a yard swing made from an inner tube was on display. It looked like an innocent enough place that might have cool souvenirs for our grandkids. Ross, always one to stay focused on the task at hand, found a few suitable gifts. I, on the other hand, apparently one who doesn't get out much, wandered around in my typical habit and honed in on an LGB poster on the back wall. Totally focused now, I hunted down a clerk who could tell me what that poster was all about. Politely refusing to rip it off the wall for me, she did give me a couple of brochures. We won't discuss here the pleading and nagging that occurred during the following months. But, in September, we ripped out a plum tree that only the squirrels appreciated, and broke ground for a 100 square foot garden railroad. I know, I know, but it was a start, right? Not to worry, we now have his and hers shovels and wheelbarrows, and a garden railway encompassing 1,000 square feet with over 200 miniature and dwarf shrubs and trees. A good variety of groundcovers mix to give a realistic look to things. The very best part? The latest expansion was entirely Ross' idea!!

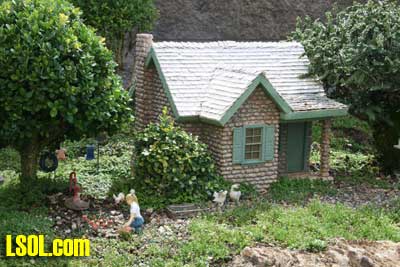

One of the discoveries that we made at some point in this process was the importance of buildings and figures to bring everything into scale and add the feel of realism to a layout. Wanting the ability to enjoy our railroad and run trains anytime with a minimum amount of fuss, we decided the structures and characters would remain in place outside all year. Anxious to move forward to the next step, after the dirt moving and digging; concrete block, irrigation and track installation; major rock placement; electrical wiring and basic plantings were finally nearing completion, and with not much left of our budget, we bought a few of the quick to assemble and relatively inexpensive plastic structures that were readily available. They filled the voids and looked fine, for a couple of years. We were disappointed to see the plastic turn brittle, the colors fade and the joints break loose. The next kit we tried was resin. This one lasted a couple of years longer, but then began to warp and come apart.  We purchased two structures of marine plywood that were advertised as perfect for outdoor garden railroads. One unit warped and was not useable within two weeks! The other continues to experience a more gradual collapse and is currently in the falling apart and extremely decrepit part of our ghost town.

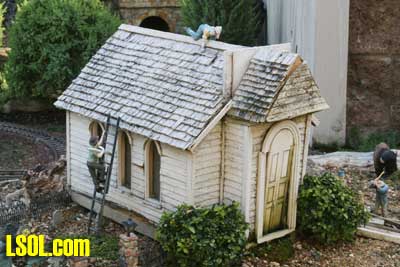

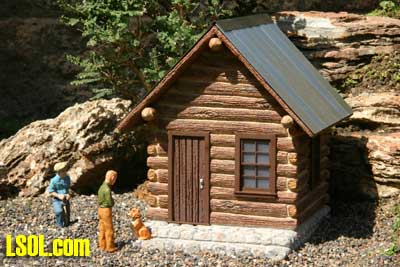

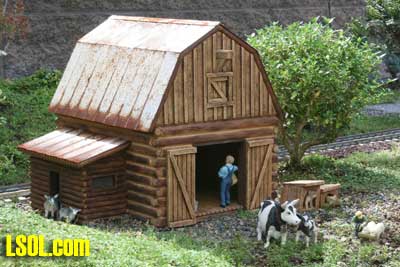

A good friend custom built a beautiful wooden church for us. Pieces continue to warp and fall off. We have Woodland Scenics construction guys continuously working to keep up with the necessary repairs with very little success.  There is a tremendous amount of excitement and pride involved in building a garden railroad and the deterioration of our buildings and other structures was disheartening. We found no newsworthy solutions until a few years ago when a couple of our San Diego Garden Railroad Society members introduced us to Precision Board. This is a non-toxic, high density urethane sheet material manufactured by Coastal Enterprises that has been tested and found to withstand temperatures from 423 degrees below zero to 300 degrees above with no degradation or breakdown. Being a closed cell product, it does not absorb moisture so it will not warp, rot or freeze. Once primed with a compatible primer, it is not susceptible to damage from UV rays and has good adhesion with any exterior type of paint.  This amazingly versatile material can be fabricated with any tools that can be used on wood, including saws, drills, routers, files, sandpaper, Dremel and dental tools, craft knives and wire brushes.  Realistic rock and stone structures and accessories can be easily created. Our first projects included retaining walls, stairways, fireplaces and fire rings, flagstone walkways and porches, fieldstone and random stone cabins, and wishing wells. These items have been outside for four to five years sitting directly in the dirt with pop-up sprinklers running one to three times a day. They show absolutely no deterioration! The only parts needing touch-up or replacement are the wood or plastic trim, windows and shingle roofs.

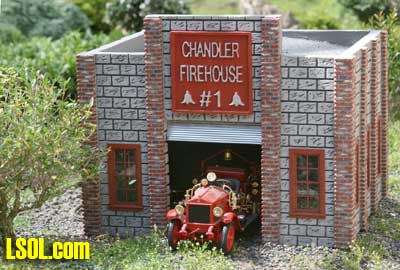

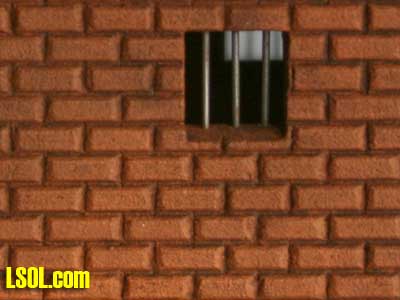

The grainy texture of Precision Board seemed like a perfect material to simulate brickwork. A little experimenting and patience proved that, with a straight edge as a guide and a small Dremel bit, joints could be carved to simulate brick. This was a somewhat tedious process, but the result was fantastic! Simple paint applications create new or used brick. Non-sanded tile grout works for grouting the joints without damaging the pre-applied paint. One of our very first projects, a two-story used brick house, remains a favorite with visitors to our railroad.   An entirely different look is easily achieved with a straight edge as a guide for joints, a wire brush for grain and a dental tool for knotholes. The resulting "wood" is more to scale than the real thing! This is great for siding, porches, platforms, stairs, doors, and trim. Since Precision Board floats and does not absorb moisture, its perfect material for a floating dock.

Imagine one basic material for so many textures and applications! Coastal Enterprises offers a lifetime of your project warranty with the condition that it was primed and finished as recommended and the finish has been maintained. Smooth surface Precision Board is available in 48' x 96' sheets in thicknesses ranging from 1/2" to 20', in 4 to 40 pound density. Contact Coastal Enterprises, phone 800-845-0745, or visit www.precisionboard.com for distributors in your area.

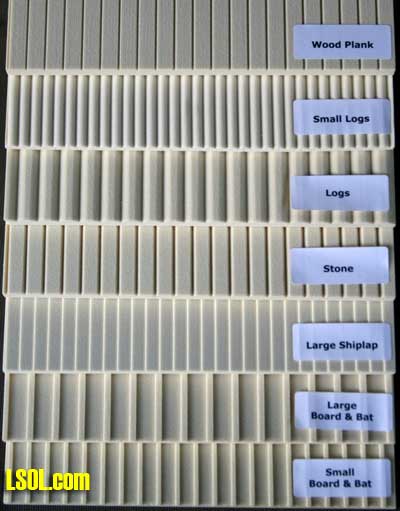

As we learned more about the unlimited uses for Precision Board, Ross began to explore fabrication shortcuts. We now have the equipment and tooling to produce 10 1/2" x 48" sheets of the material with eleven different patterns. A few of them, including brick and two sizes of stone block, still require some carving, but the majority of the work has already been done. The two sizes each of logs and wood plank require only wire brushing for grain.

Several patterns, such as the two sizes of either board and bat or shiplap siding, can be used with no added fabrication or can be wire brushed for additional texture. The two-shiplap siding patterns can also be used for composition shingle or wood shake shingle roofing material with a little carving and wire brushing.

The pattern sheet material is manufactured and sold by our company, Rainbow Ridge, phone 619-561-0643 or visit www.rainbowridgekits.com. Rainbow Ridge also offers kits and finished projects. A sample pack of the eleven patterns, basic instruction info, product catalog and price sheets is available for $5 to cover shipping and handling. This is refundable on your first order.

We believe Precision Board to be the material we have all been searching for that will put an end to the problems of deterioration and loss of our railroad structures due to outdoor exposure. It being so versatile and easy to work with is a special bonus!

| Precision Board |

| What is the best adhesive to use with Precision Board? White glue, carpenter's glue, Liquid Nails For Small Projects, super glue, silicone rubber, etc. ? And what is the proper primer to use with this product? Thank you. |

| Rex Davis - 09/03/2008 - 09:47 |

| Comment |

| Thanks for this lovely article. The buildings look incredible. Any chance this product has come south enough to be available in the SE? Great concepts... Elaine |

| Elaine Haggenbottom - 09/03/2008 - 10:50 |

| PB Primer & Adhesives |

| Rex, Coastal Enterprises, the manufacturer of Precision Board, makes a water based primer filler "FSC-88-WB" specifically for Precision Board. It is an expensive product available only in gallon quantities from the manufacturer. Rainbow Ridge repackages and sells it in half pint sizes. The primer is included in all Rainbow Ridge kits. For gluing raw Precision Board pieces, a polyurethane glue like Gorilla Glue is best. We miter the joints, apply the glue sparingly along the inside edge, mist with water, and clamp or shrink wrap the pieces together. A gel type Crazy Glue can be used if applied in a continuous bead and then clamped or sprayed with quick set. For primed, painted and sealed Precision Board pieces, clear silicone works best, especially when adhering different materials (such as metal roofing or plastic windows) where expansion and contraction will vary. For small trim pieces where expansion and contraction are not a concern, a continuous bead of gel type Crazy Glue will suffice. |

| Sue Piper - 09/03/2008 - 22:27 |

| PB Availability |

| Hi Elaine, Thank you for the favorable comments! Rainbow Ridge does not have distributors but will ship assembled kits or pattern sheet material to anywhere in the continental U.S. We have also sent product to Canada, New Zealand, Australia and England. |

| Sue Piper - 09/03/2008 - 23:07 |

| Precision Board |

| Will have to experiment with this. I never heard of it. The only success I've had with my buildings is to use planed down cedar or redwood. I'm looking forward to trying some. Will send for your sampler. |

| Joe Wilson - 09/05/2008 - 15:39 |

Top of Page

|