Scratch & Bash

:

Accessories

This Cradle Will Not Fall or Fail

Feb 23, 2011

By Noel Widdifield |

Author

Bio

As I thought about the engine cradle I had up in Maryland, I remembered that it was made from a very firm, but pliable foam. So I went to my trusty Mac and opened Firefox and Googled "foam". When I did that I found was the solution to my problems.

|

Back in December 2007 Barry Reade posted an item in The Workshops that caught my attention. He asked if anyone had any idea how to design something that would hold his locomotives while he was working on them. This post generated a lot of ideas for a cradle that would hold the loco safely. Our members always have good ideas on almost any subject. There were ideas and pictures for a wide variety of cradles ranging from a very sophisticated one with a swivel base to one made from a cardboard box.

The subject came up again in June of 2010 when Ron Hill posted a question about constructing a cradle to work on his locos rather than continuing to do it on his kitchen counter. This time Gary Condry provided a photo of the cradle the he had fabricated.

I even joined the discussion with a photo of a cradle that I had purchased several years ago but was no longer available for sale.

Both of these discussions in the LSOL.com Workshops continued to run through my mind from time-to-time and I tried to think of a solution to the cradle dilemma.

There was even the innovative Light Duty Maintenance Stand design by Bill Ness just a few weeks ago in an article here at LSOL.com. Who would have thought pencils would make a great way to support rolling stock and engines.

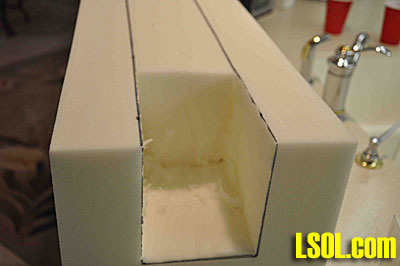

Following my completion of my NYC GP-9 being repaired and finishing up my Aristo Craft caboose modification, I decided to spend some time trying to figure out how to fabricate a cradle like the one I had purchased so long ago. Those two projects were more difficult than they could have been since I didn't have my cradle down in Florida with me. As I thought about the one I had up in Maryland, I remembered that it was made from a very firm, but pliable foam. So I went to my trusty Mac and opened Firefox and Googled "foam". When I did that I found one of the entities was "Foam Cushions-Custom Cut" with a url of www.buyfoam.com When I went to that site I discovered that the company BuyFoam had a wide variety of foam products that would allow you to select a range of foam firmness and you could specify the size and general shape of the foam you needed. The choices in shapes include: circle seat cushion, mattress or cushion, T-cushion and L-cushion. I decided the mattress or cushion shape was the one best suited for the cradle. So I ordered a piece of the "very firm" (XL-48) foam. I specified a piece 30 inches long, 10 inches high and 10 inches wide and placed the order. It took about 10 days for the foam to arrive and when I opened the large box, I was pleased to find that the form pretty much matched the firmness and texture of that used in the cradle I had purchased years ago. I placed the foam on a flat surface and began to figure out how I would cut out the trough that would form the actual cradle for holding the locos and rolling stock. To determine the size of the trough, I measured my GP-9 and decided to make the width 4 1/2 inches and the depth five inches. I then marked lines on the foam to serve as guides for cutting out the trough. I used a Sharpie permanent marker to draw the lines.

My next problem was figuring out what I would use to cut the foam to shape the trough. Had I been in Maryland I would have first tried my table saw to make the cuts for the sides of the trough, but I wasn't in Maryland and didn't have a table saw. Since I was doing this work on the counter between the kitchen and dining room, I happened to notice the knife block with an array of kitchen knives. Since my wife is very supportive of my hobby and even, at times, recognizes my hobby skills, I decided to see if any of the knives might work to cut the foam. I tried the paring knife, the serrated knife and the large butcher knife before selecting the butcher knife as my tool. I found that it cut the foam easily and smoothly.

Because the knife blade is about six inches long, I put a mark on the blade at five inches so that I would know how far to cut down into the block. I proceeded to cut the depth cuts along the entire length of the block. Once those two cuts were made I cut across between the two side cuts at about five inches from the end. I then carefully cut across the bottom of the trough and after cutting again in each original cut to loosen the resulting block of foam, I lifted the resulting 5"x 5" x 4 1/2" block of material out. This resulted in very smooth sides, but a slightly uneven bottom of the trough. It is difficult to control the level of the cuts across the bottom of the trough, but I wasn't worried because I had planned to line the trough with material.

I continued to cut and remove five more similar blocks of foam until I had completed the trough. I then smoothed the bottom as much as possible and removed all of the excess bits and pieces of foam. There are a lot of loose pieces of foam involved with this process.

Because I didn't have the material to line the trough, I used a towel as a temporary liner to try out the cradle. That worked some well that I believe that I decided to use a towel for the final lining.

The final product turned out to be as nice as the one that I purchased those many years ago and will be a great addition to my growing set of tools in our Florida home. I tried it out with my GP-9 and modified caboose and it seemed to work just like the one I had purchased.

When I look at the finished project, I believe that I could have made the dimensions 24 inches long, ten inches wide and eight inches high and that would have been adequate for most of my work. That would have saved me some money as well. The foam cost $29.17 plus shipping and the towel was $2.67 at Wal-Mart. This was a very simple project and can be done in about an hour once the foam arrives. This would be a great project for one of those dark and snowy nights up north. Just be very careful with the large butcher knife if that is how you decide to cut the trough. It is probably possible to use a saw to make the cuts but that would be kind of tricky too. If anyone builds one of these and uses a saw, let us know how you did it. Oh, and by the way, my wife, Ann, was pleased that the operation didn't seem to damage the knife and the only result was a line on the blade drawn with the permanent marker. I explained that it would wear off in time. I hope that stuff isn't toxic.

| Maintenance Cradle |

| Noel, I need one of those!! It looks like it would hold a Big Boy, and those things are really heavy - much too heavy for pencils. As always, you did a great job with the text and photos. Bill |

| Bill Ness - 02/23/2011 - 03:05 |

| Cradle |

| Great idea Noel. It looks soft and sturdy. Nice job!! |

| Gary Condry - 02/23/2011 - 04:05 |

| Cutting foam |

| I have not tried this in creating a cradle yet, but in past projects, that I used foam in, I found that an electric knife works wonderfully in cutting the foam. |

| TJ Forshee - 02/23/2011 - 06:21 |

| Maintenance Cradle |

| Noel, Another worthwhile how-to article that will make working on our equipment much easier. Well written and illustrated. Now with the "pencil" cradle for light equipment and your foam cradle for heavy equipment,just about any maintenance task will be easy to accomplish. |

| JD Miller - 02/23/2011 - 07:28 |

| Try this |

| Try this: use an electric knife. works wonders in the foam and shouldn't have as many rugged edges on the bottom |

| Gerri Miller - 02/23/2011 - 07:41 |

| cradle |

| Thanks for the info, I made one like your first photo to work on my F-3. Got the 3/4 inch foam from Joan's fabric, and was told by them, the best way to cut the foam is to use an electric knife. It worked great, glued the foam on 3/4 " Pine and it know works on all my equipment. |

| John Dodge - 02/23/2011 - 09:02 |

| Cradle |

| The suggestion to use an electric knife is a good one. I wouldn't have thought of that because I hate to use them for carving meat and we don't own one. Now when I return from vacation, I will borrow one from a friend and trim up the bottom of the cradle. We learn something new every day. Thanks, Noel |

| Noel Widdifield - 02/23/2011 - 09:37 |

| Cradle will rock |

| I saw this cradle at Cabin Fever Expo but I like the Piper Box myself [img]http://www.largescaleonline.com/eimages/lsolpics/Team_Member_Pics/glenhabr/Train_Shows/Cabin_Fever_Expo_2011/11CFE015.jpg[/img] |

| Glenn Habrial - 02/23/2011 - 13:31 |

| soft |

| I like yours too because of the foam. |

| Glenn Habrial - 02/23/2011 - 13:36 |

Top of Page

|