Power, Sound, R/C

:

Remote Control

An Introduction to DCC - Part 5

Feb 7, 2002

By Fred Hughes |

Author

Bio

Once DCC is installed we can control virtually an unlimited number of trains with our Hand Throttle

|

Once DCC is installed we can control virtually an unlimited number of trains with our Hand Throttle; our REFLEXES will determine the maximum. Most of us enjoy being the "Engineer" and are satisfied to operate a couple trains at a time. How many trains I am able to operate at one time is inversely proportional to my age. Twenty years ago I could watch four!

To control more we have the option to plug-in additional throttles so our friends/kids can control their own trains. But what about preventing those "Cornfield Collisions" when controlled by an engineer or allowing the trains to operate unattended.

"SOMETIMES IT'S FUN TO PUT DOWN THE THROTTLE AND JUST WATCH-EM RUN!" |

In the publication "Digital Command Control - the comprehensive guide to DCC -" Page 92, Chapter 7.9 "Stopping locomotives in front of a red signal" gives us one method to implement automatic controls.

Some mobile decoders are designed to either brake to a stop if they encounter DC current or continue running at the same speed depending on the polarity of the DC current. This feature gives us ONE method of stopping at a red signal. A second method of stopping is broadcasting a "Set Speed Zero" command using a special "Packet Generator".

Depending on the decoder installed in our trains one method or the other can be used to stop the locomotives and the command to stop can be triggered either by our Hand Throttle or automatically by sensors in the layout. DCC opened new options for braking. Instead of cutting power we can simply send a "Set speed Zero" command or switch track power to DC then, depending on the "Braking Momentum" preset in the locomotive mobile decoder, the train will stop as slowly or as rapidly as desired.

Figure "A" illustrates one simple method for braking in an isolated section of track. Using simple track sensors to trip DPDT relays that switch power from Normal DCC to "Set Speed Zero" or DC.

Click for larger picture Click for larger picture - When the isolated block of track is vacant Normal DCC power is supplied to the isolated block by the control relays.

- When the "TEST" sensor is triggered by a train entering the control block the isolated TRACK segment will:

- Continue to receive normal DCC power if previously the last sensor triggered was the "RELEASE" trigger. In this case the train will proceed as normal through the control block.

- Switch to "SET SPEED ZERO" or DC power if the "BRAKE" was the last previous triggered sensor by a preceding train and the locomotive will begin to brake using the braking momentum value for that engine.

- The locomotive will continue to brake until the preceding train triggers the "RELEASE" sensor.

- When the "RELEASE" is triggered the locomotive will begin to accelerate using the momentum value for that engine.

|  |

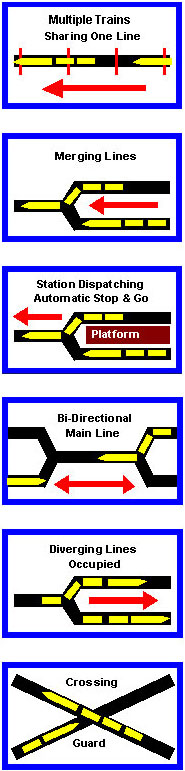

Besides stopping at signals there are many occasions for automatic braking on our layouts. The diagrams to the left are just some of the "Cornfield Collision" opportunities mentioned in the first of this series.

Automatic control of the above situations can be accomplished by several different methods when operating under DCC. LGB offers products designed to stop trains at a signal by using their "EPL" switch mechanisms to cut power on a conventional DC layout. This method produces a rather abrupt stop. This method has been enhanced with additional custom circuits to increment the power drop to 2 or more steps and is offered commercially by Ingram Automatic Controls at www.track2.com/ingram/. These products are not DCC compatible. It is, however, possible to adapt the LGB EPL approach to DCC operations. |

Another control method requires computer software. DCC is computer control and therefore capable of integration with today's personal computers. Various companies offer software and interfaces to accomplish this. Railroad & CO is a major supplier of automatic dispatching and routing software for use with DCC. Their web site offers multiple options that may be of interest. See www.freiwald.com. This approach is more complex and requires a greater learning curve. Sky is the limit however, if you are willing to make the commitment.

My first "Control Blocks" were fashioned with LGB components but as I added more features to the Garden the cost of LGB EPL switches and motors encouraged me to find a better solution. $100 per Block became expensive and in addition to simple control of multiple trains on a single line I desired to have other traffic controls. I looked for dispatching controls where I could have a train enter a station and stop at a passenger platform where it would be held until another train on a parallel line entered the station. Then have the trains released one by one to a main line. Automatic crossover protection, staging ladders, bi-directional traffic were some of the conditions that interested me. None of these DCC accessories were commercially available so the only choice was to build my own.

Once I developed the automatic controls for my garden, guests requested information on where they could be purchased. Because the controls were custom built I could only offer the wiring schematics for the main line "Block Control" and "Station Control" using LGB products to those interested in assembling their own. These diagrams are available at no charge.

The balance of this article briefly describes the products developed to control traffic on the Hiwan Loop and other railroads and is devoted to describing specific control circuits and which ones are available as DCC accessories from www.DCC-BitSwitch.com

DCC-BitSwitches

Because many folks did not wish to build their own controls, and the LGB solution became cumbersome for applications beyond "Block" and "Station" situations, I created DCC-BitSwitches.

Checking the direction of a turnout and simultaneously the condition (vacant-or-occupied) of the directed spur was better handled by different approaches. BitSwitches solve these and other problems. KISS was the goal for the BitSwitch products. Whenever possible the number of track sensors (things to wire) was limited to ONE per "Controlled Segment". To power the LGB switch motors AC current is required. Braking required analog DC in addition to normal DCC. This meant 3 power supplies, AC DC and DCC. BitSwitches use ONE power source for everything.

LGB EPL products are excellent but when purchased in the numbers required for automatic controls, expense sets in. The LGB parts alone for the "Block Control" is 2 switch motors, 2 EPL switches and 4 track contacts. Total cost $106. Parts for the "Station Control" was 6 switch motors, 10 track contacts. Total cost $300. DCC-BitSwitch "Block" total cost is $34.95 and "Station" $69.95.

Current DCC-BitSwitch product offerings include controls for:

- Multiple trains sharing a main line "Block".

- Station dispatching "Station"

- Shared Bi-Directional main line

- Merging lines "Merge"

- Diverging lines "Spur"

- 2 way crossover "2 Way"

- 4 way crossover "4 Way"

- Yard control "Siding"

- Automatic staging ladders

For additional information visit www.DCC-Bitswitch.com.

Top of Page

|