Scratch & Bash

:

Engines / Rolling Stock

Simple self-propelled Track Cleaner

Sep 24, 2008

By Bruce Jahn |

Author

Bio

When our railways were young, cleaning track was a duty that was handled with interest and enthusiasm.

|

When our railways were young, cleaning track was a duty that was handled with interest and enthusiasm. When it became a chore, we started thinking about a switch to battery power. But I like track power, and pulling a track cleaner around behind a track powered loco didn't make much sense to me. My solution was to build a simple, cheap cleaner that works good no matter how bad I've let the track become.

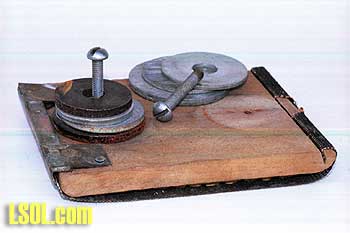

The primary cleaning tool is a shaped wood block wrapped with drywall sanding "screen". Determined by a half sheet of screen, a 3/8 inch thick, 3 1/4" wide by 4 1/4" long piece of wood with the bottom ends rounded was the right size.

A saw slot cut in the top on one end allows the screen to slip in. The screen is pulled around the end, sandwiching a layer of compressed sponge from the grocery store allowing the screen to bend over the top of the railhead. The other end of the screen is held in place by a soldered brass angle and two tiny wood screws into the top of the wood. The sanding block is allowed to float along the track, but weighted down by several large washers.

My track cleaner is powered by a motor block which I got with a phone call from Aristo Craft parts department, but any power block should work. If your motor block used skates, I would remove those as they're merely extra drag, plus in my case, would interfere with the lead weight.

Sometimes, sticks or stems from a nearby ivy used to cause the power truck to run up over the rail and end up in a "wheels turning but not going anywhere" situation. I needed some extra weight added to the power truck. I nailed together a simple wood mold to pour a lead weight. My smelting crucible is nothing but a soup can with a handle attached. I drop a few automotive wheel weights in the can and run a propane torch under the can until the lead melts.

The steel parts of the weights, and some debris float to the top, but it's easy to pour the molten lead into the mold. After the lead is poured, I dump the left over trash from the can and am ready for my next smelting job. Make sure you do this operation outdoors with good ventilation or you might spend the next couple days on the sofa with a horrible headache and upset stomach, to say the least. I hold the finished weight in place with a couple 0.030" strips of brass and 440 screws driven into the lead. The weight merely hangs from the top of the motor block.

For the main frame of the track cleaning car, I used 1/8" and 1/16" thick plexiglas, which is cheap from the scrap bin at my local plastic store, but wood would work as well. I make good use of the scrap bin and lots of my projects are built around plexiglas, including the trestle shown under the track cleaner in operation...but I'll save that data for another story. Before actual construction of the frame, I lined up all the parts to see how short it could be. Width was determined by an old .5 amp hour battery lying on its side.

The frame consists of the two 1/8" thick side rails and four 1/16" inch thick spreaders. The motor block swivels on one spreader, the rear truck on the second, and the center spreader carries the sanding block. A fourth spreader holds the on/off switch and the receptacle for a wall charger plug. Two sets of smaller plexiglas pieces in the shapes of right angles hold the battery in place. The bottom center spreader has two oversized holes drilled on the machine centerline and allows two 10/24 screws which screw right down into the wood block to slide along the track. The end two spreaders have holes drilled on the centerline to accept small bolts loosely from the motor block and rear truck, which allow both to rock and stay in contact with my sometimes lousy track. For this machine, I'm using a 12 volt, 1.2 amp hour lead acid battery available at most stores catering to RC enthusiasts or electronic supply houses such as Digi-Key or Mouser. The battery is wired through a small receptacle which accepts the wall charger, then through a toggle switch to turn the machine on and off. Since my sprinklers sometimes come on while the machine is on the track, I place an electrician's wire nut over the toggle switch to protect it from the water...a lesson I learned too late.

I merely place my track cleaner on the track, switch it on and forget it for two or three hours. When I remember (sometimes the next day), I put it back on the charger and forget it again until next time. The lead acid battery doesn't build a memory like most popular batteries, so it's OK to leave it on the charger for a month or so. After about six years of heavy use, I finally did replace the old .5 amp hour battery since the abuse I give it lowered the run time to only about 20 minutes. I assumed the sanding screen might leave behind some sort of dust, so I thought to drag the dust along until it falls off the rail head somewhere along the line. To do this, a pair of fiber brushes are attached to the underside of the trailing truck. I merely cut part of the handles off cheap acid brushes, available at most craft stores. I folded the remainder of the handles at about 90 degrees, soldered the two brushes together and drilled a hole for the main truck bolt. This allows the two brushes to wipe the track between the two axles of the trailing truck. Folks have suggested I build a wild looking body over the machine, but I've kept that project on a back burner in the interest of keeping this cleaner easy to handle and use. I've also heard concerns about wearing down the rail with this type of sanding screen, but I can't detect any wear yet on my code 250 NS rail, so the rail should hold up under lots more passes.

| Track Cleaner-Very Informative |

| Bruce, I like your straight forward approach to building a track cleaner. Not too complicated and it will do the job. Thanks for taking the time to share your track cleaner and how it was built. JD |

| JD MIller - 09/24/2008 - 07:35 |

| Track cleaner car |

| I have an older USA boxcar labelled for 'Old Dutch Cleanser.' I use it just like the old HO track cleaners that we use to use. Just a simple masonite slider between the trucks and under the truss rods, suspended by two bolts with light springs to hold it down on the track. I then cover the masonite with a scotch brite plastic pad. Simply tow the car in your train and in a few laps around the rail tops will shine without the risk of cutting scratches which ultimately attract dirt. I use the same scotch brite sanding pads in a pole sander to clean particularly dirty spots (from tree sap and aerial bombers). Don't use sandpaper or the screen type drywall sander as it will definitely scratch the railhead. |

| Mike Evans - 09/24/2008 - 07:43 |

| track cleaner |

| I use a piece of 1/2 Lexan for the body of my cleaning car. Plywood will also work. The Scotch-brite pads are the best and really do a good job cleaning the rail without scratching the rail. I added a direction switch to help in stub track situations. My battery is held on by velcro straps. |

| Walter Bringsauf - 09/24/2008 - 09:01 |

| Self Propelled Track Cleaner |

| This sounds and looks like the exact answer I need for my overhead system as cleaning the track can be problematic and always need the use of a ladder of some sort to get to the track. Thanks for the great idea. I plan on putting it to use soon. I also like the comment made by Mike Evans and am looking at using his idea as well. I would use my USA Trains GP7/GP9 engine to pull it around the track. Thanks for both of these GREAT ideas for track cleaning guys. |

| Gerry Keffer - 09/24/2008 - 11:11 |

| Rail Cleaner |

| I use abrasive blocks from WWW.THERUSTSTORE.COM The Rust Store has several grades of abrasive pads available. Fine,medium and coerce .It appears that the material is the same stuff that LGB uses on their track cleaner engine. I HAVE an RC battery powered ARISTO SD45 that I pull the block around the track. The block is mounted in a CENTER LINE CLEANING CAR. HOPE THIS HELPS MIKE |

| Michael Gruber - 09/30/2008 - 16:30 |

Top of Page

|